Job automation is fundamentally transforming the U.S. manufacturing sector. From advanced robotics and artificial intelligence to smart factories and predictive maintenance, automation is reshaping how American goods are produced faster, cheaper, and more efficiently than ever before.

While automation has boosted productivity and global competitiveness, it has also raised serious questions about job displacement, workforce skills, wage structures, and the future of factory work in the United States.

This article examines how automation is affecting U.S. manufacturing industries, both positively and negatively, and what lies ahead.

1. What Is Job Automation in Manufacturing?

Job automation in manufacturing refers to the use of:

-

Industrial robots

-

Artificial intelligence (AI)

-

Machine learning

-

Automated assembly lines

-

Computer-controlled machinery

-

Smart sensors and software systems

These technologies perform tasks that were traditionally done by human workers—often faster, more accurately, and at lower long-term cost.

2. Why U.S. Manufacturers Are Adopting Automation

U.S. manufacturing faces intense pressure from:

-

Global competition

-

Rising labor costs

-

Skilled labor shortages

-

Supply-chain disruptions

-

Demand for higher productivity

Automation helps manufacturers:

-

Reduce production costs

-

Increase output and consistency

-

Improve workplace safety

-

Remain competitive against low-cost countries

For many firms, automation is no longer optional, it’s essential for survival.

3. Jobs Most Affected by Automation

Automation has the biggest impact on repetitive and routine manufacturing jobs.

High-risk roles include:

-

Assembly line workers

-

Machine operators

-

Packaging and sorting staff

-

Quality inspection roles

-

Material handling workers

Robots excel at repetitive tasks, leading to reduced demand in these job categories.

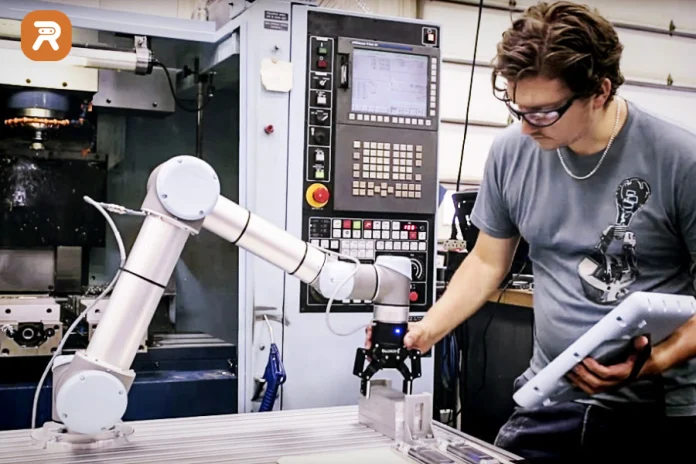

4. Jobs Created by Automation in Manufacturing

Contrary to popular fear, automation does not only eliminate jobs and it also creates new ones.

Growing job roles include:

-

Robotics technicians

-

Automation engineers

-

Software and AI specialists

-

Maintenance and systems analysts

-

Data and production planners

These positions typically pay higher wages and require advanced technical skills.

✅ Key takeaway:

Automation shifts jobs rather than destroying manufacturing employment entirely.

5. Impact on Manufacturing Employment Levels

U.S. manufacturing employment has declined over the long term, but automation is only one factor.

Other contributors include:

-

Global outsourcing

-

Productivity gains

-

Trade competition

-

Changing consumer demand

In modern automated factories, fewer workers produce more output a clear sign of productivity growth driven by technology.

6. Productivity and Output Gains

Automation has dramatically increased manufacturing productivity.

Results include:

-

Faster production cycles

-

Lower defect rates

-

Consistent product quality

-

Reduced downtime

This allows U.S. firms to:

-

Produce domestically rather than offshore

-

Respond faster to market demand

-

Strengthen supply-chain resilience

Automation has helped bring some manufacturing back to the U.S. through reshoring.

7. Wage and Skill Polarization

Automation has created a divide within the manufacturing workforce.

Effects include:

-

Higher wages for skilled technical workers

-

Stagnant or declining wages for low-skill jobs

-

Increased demand for STEM-related skills

Workers without retraining face rising job insecurity, while skilled workers see better career growth.

8. Automation and Workplace Safety

One major benefit of automation is improved safety.

Robots now handle:

-

Heavy lifting

-

Dangerous chemicals

-

Extreme heat environments

-

Precision cutting and welding

This reduces workplace injuries and long-term health risks for human workers.

9. Small vs Large Manufacturers: Uneven Impact

Large manufacturers:

-

Can afford automation investments

-

Scale technology quickly

-

Gain strong productivity advantages

Small manufacturers:

-

Face higher upfront costs

-

Risk being left behind competitively

This creates consolidation pressure within U.S. manufacturing industries.

10. Automation, AI, and Smart Factories

Modern U.S. factories are evolving into smart manufacturing systems, using:

-

Real-time data monitoring

-

Predictive maintenance

-

AI-driven demand forecasting

-

Fully integrated supply chains

These technologies increase efficiency but reduce reliance on manual labor.

11. Government and Policy Responses

The U.S. government supports adaptation through:

-

Workforce training programs

-

Technical education funding

-

Apprenticeship initiatives

-

Manufacturing innovation grants

Policies aim to ensure workers can transition into automation-related roles rather than exit the labor force.

12. Does Automation Threaten the Future of U.S. Manufacturing Workers?

Automation does not mean the end of manufacturing jobs—but it does mean manufacturing jobs are changing.

Key realities:

-

Manual roles are shrinking

-

Technical roles are expanding

-

Lifelong learning is essential

-

Adaptability determines job security

Workers who reskill remain highly employable in automated factories.

13. The Long-Term Outlook for U.S. Manufacturing

Looking ahead:

-

Automation will continue expanding

-

AI integration will deepen

-

Factory employment will stabilize at lower but higher-skill levels

-

Output and productivity will continue rising

Countries that embrace automation while investing in workers will dominate future manufacturing.

Conclusion: Automation Is Reshaping—not Ending—U.S. Manufacturing

Job automation is fundamentally altering U.S. manufacturing, improving productivity, safety, and global competitiveness while challenging traditional employment structures.

The future of American manufacturing depends not on resisting automation, but on preparing workers for a more technical, data-driven, and automated industrial economy.

Those who adapt will thrive. Those who don’t risk being left behind.